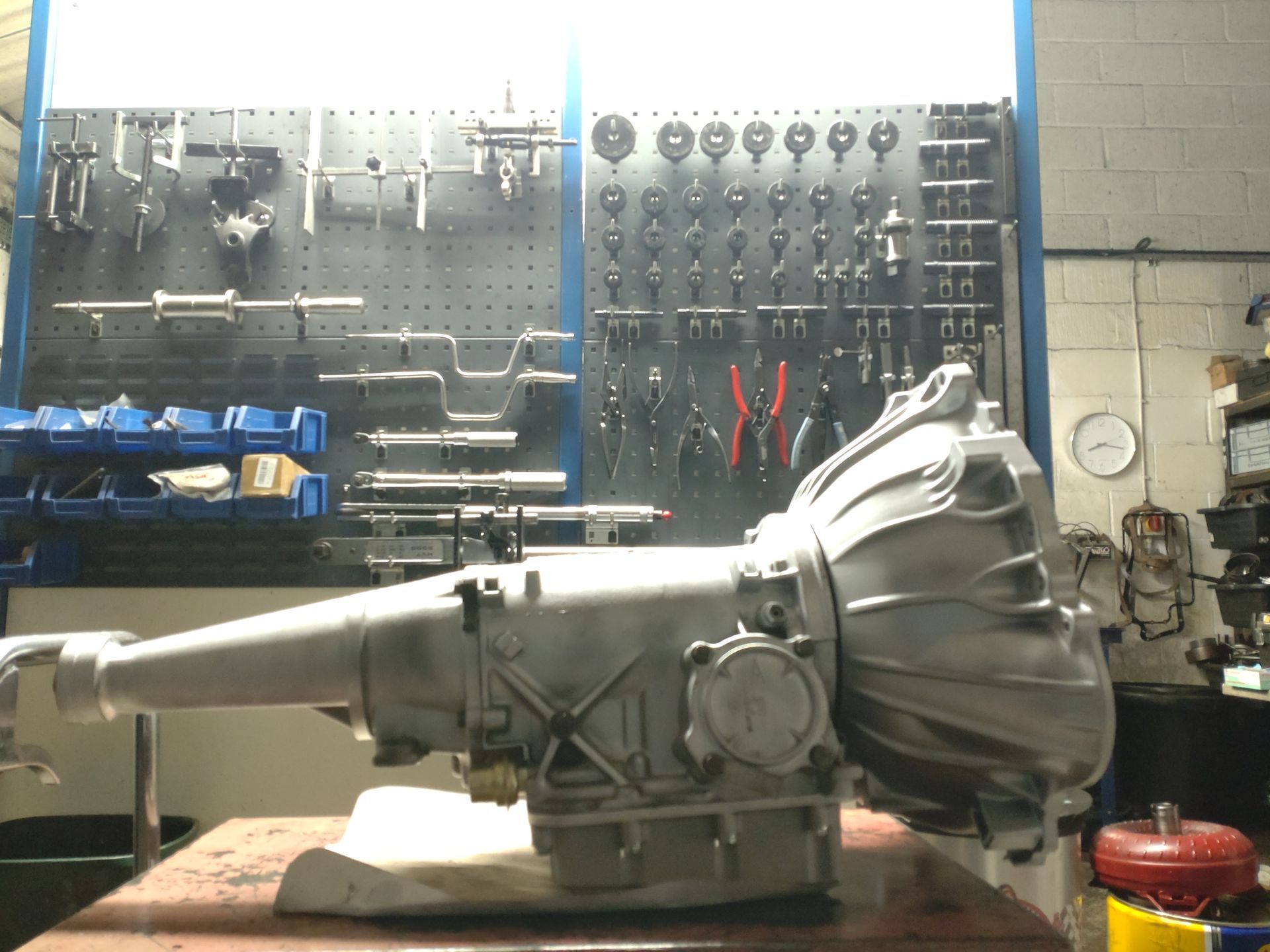

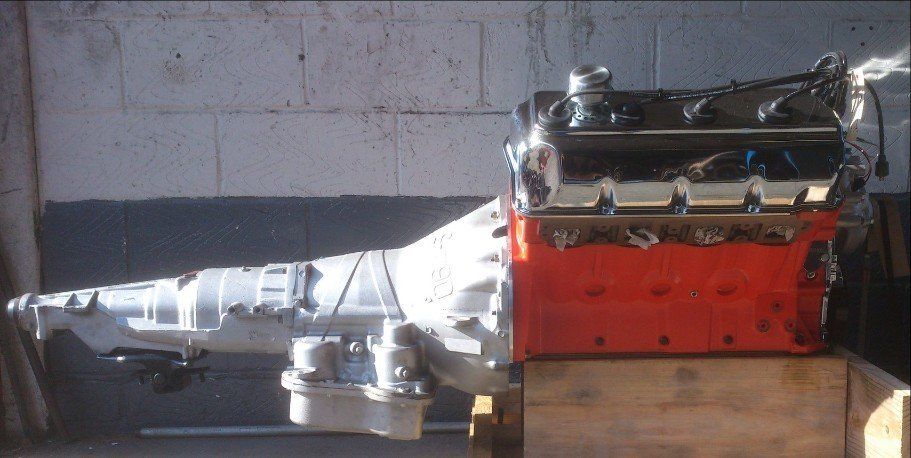

We recondition, service and repair transmissions for all Classic, American and Prestige vehicles from the 1940's to present day. All of our transmissions are built using the highest quality parts sourced from worldwide locations, then assembled with the greatest of care by our experienced team ensuring every unit is built to a fine tolerance and are finished off in an aluminium paint. After the rebuild process is complete the transmission is then tested on our transmission Dyno to ensure all transmission pressures, shifts and cooler flow are correct.

We also carry out a range of performance transmission modifications & upgrades to improve shift quality and durability where required.

(Dyno testing is subject to vehicle application)

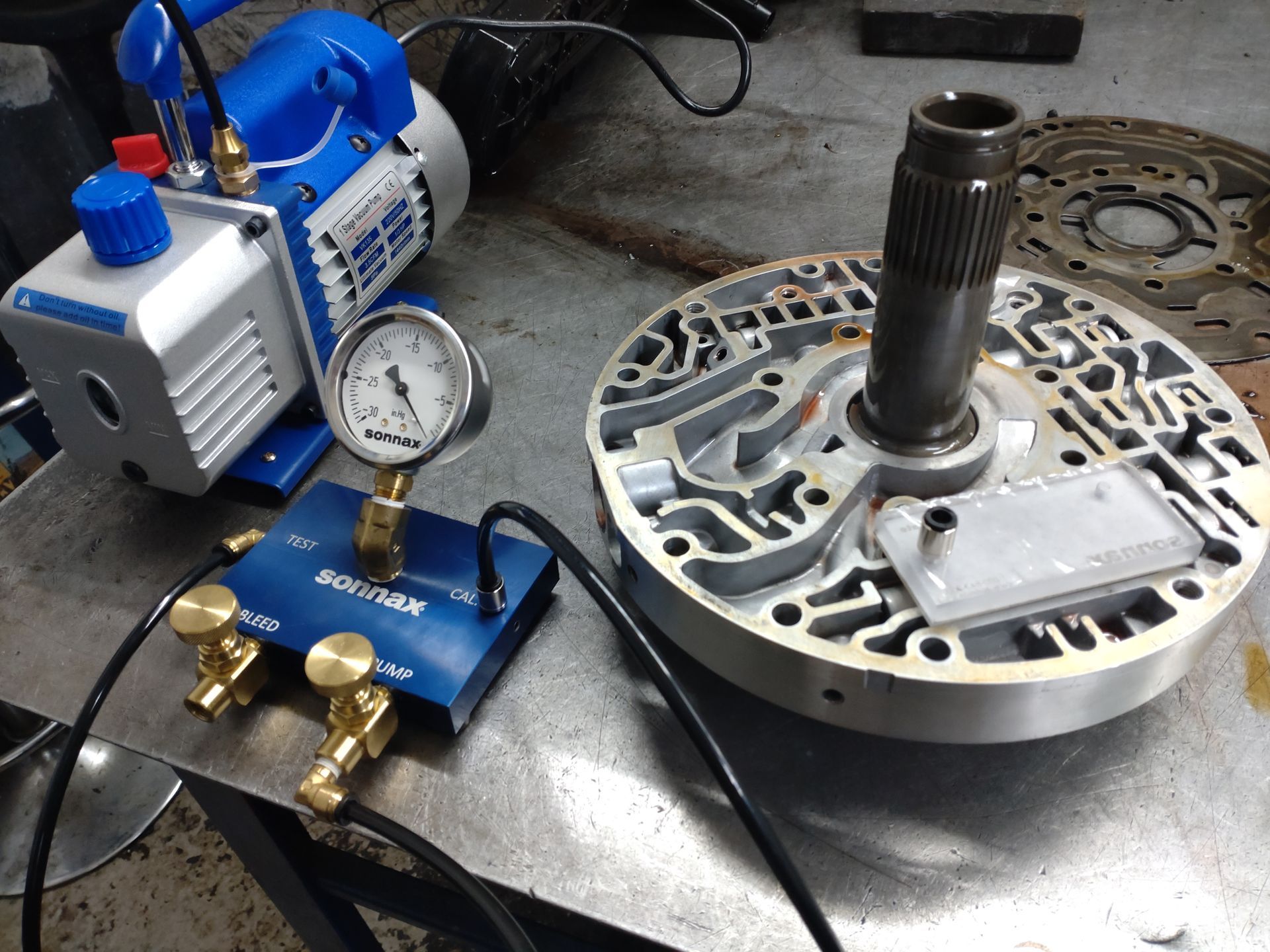

Our workshops have the facility's to carry out full diagnostics of your transmission, this ensures the correct repair work will carried out prior to the removal of your transmission. During the removal and re-fitting process it is important that correct procedures are followed including, checking cooler lines, propshaft uj's, flexplate for damage or deterioration. It is also important to flush the transmission oil cooler to prevent contamination entering your reconditioned transmission leading to shift concerns and premature failure. That is why we have invested in the tools and equipment to ensure this process is carried out correctly.

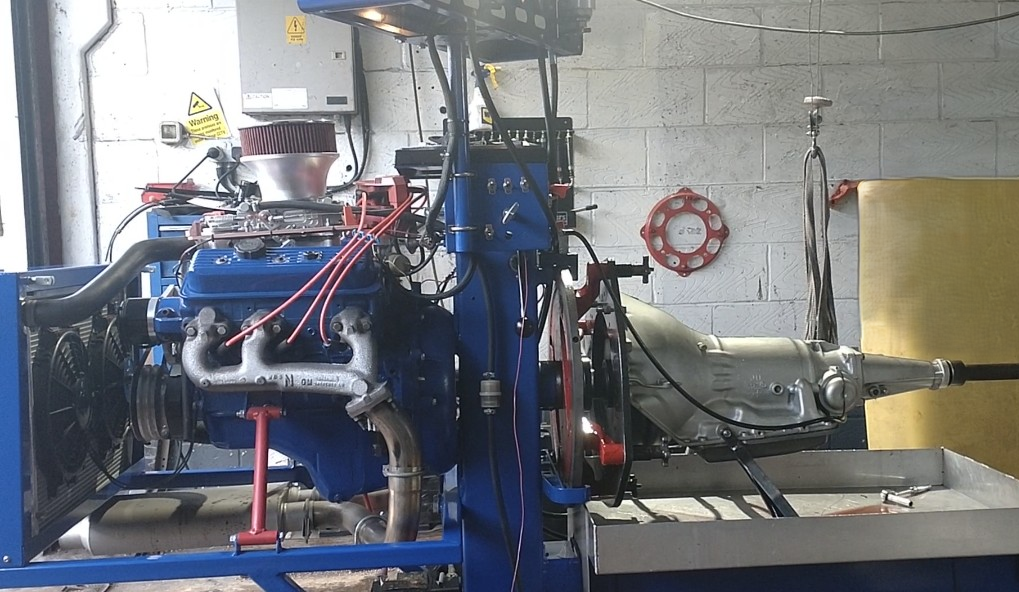

Our Transmission Dyno

Our in house transmission Dyno give us the ability to test the transmissions we build. This process allows us to carry out the initial break in of the transmission and ensures the transmissions line & clutch pressures, cooler flow and cooler pressure are all within specification and the transmission is shifting correctly.

The Dyno is powered by a 4.3L Chevrolet V6. Cooled by a large aluminium radiator with twin Derale electric fans and Evens waterless coolant. The load on the transmission is created via a heavy weighted hub with the addition of a large diameter Wilwood brake rota with a signal Wilwood four piston brake calliper. During the test procedure the transmission fluid is double filtered , this ensures that any partials created during the break in procedure do not recirculate back into the transmission.

Since the accusation of our transmission dyno, it has not only proved itself an invaluable piece of equipment for testing purposes it has also given us the opportunity to carry out further research and development on the transmissions we build.

As an example we noticed the cooler flow Ford C4 and C6 transmission was fairly low in comparison to other transmissions. So we were able to carry out some internal modifications that have increased the cooler flow by 50%. This in turn also improves lubrication the the geartrain and thrust washers, thus increasing the longevity of the transmission.

Our dyno is a constant process of evolution. We can currently test the majority our the transmissions we build, however we are always looking to increase the list of transmissions we are able to run on the dyno.

Some of our most popular transmissions are listed below